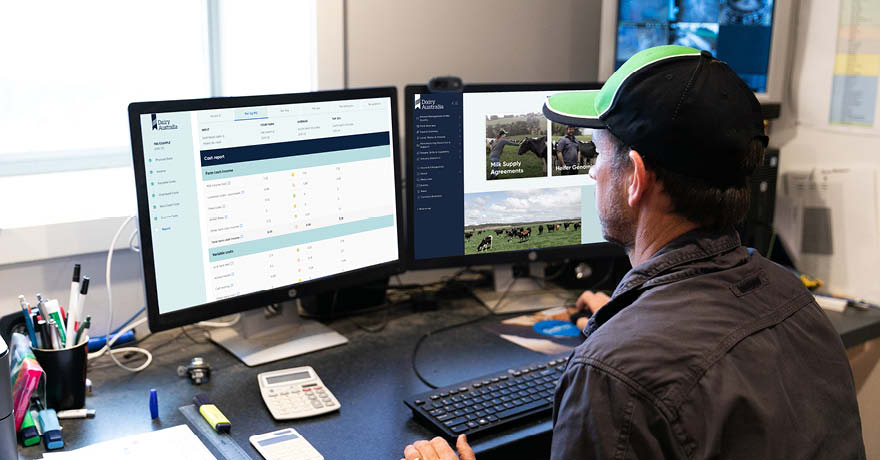

Providing dairy farmers with access to business planning and risk management tools and insights to support on-farm decision making and improve profitability.

Dairy Australia works across all regions to build farm business capability and equip farmers to make better decisions that increase profit and wealth over time. We want farmers to achieve their long term business and personal goals.

Our Farm, Our Plan

Our Farm, Our Plan helps farmers identify long term goals, improve business performance and manage …